Principles of operation

The Rotary Tube Divider (PD) is designed for representative dividing of bulk material.

Download Rotary Tube Divider brochure (PDF)General description

The drive unit rotates a dividing tube, where the material stream is constantly poured in a spherical pattern on the inside of the bottom cone. The slot opening(s) in the bottom cone extract(s) a quantity corresponding to its width and the rest passes into the reject outlet.

The dividing ratio is adjusted by setting the damper in various positions and thereby decrease/increase the opening in the bottom cone. The division ratio is steplessly adjusted between 1:8 and 1:89 – dependent of PD model and particle size.

The Divider essentially consists of the following units:

- Drive unit

- Dividing tube

- Top cone

- Bottom cone

Technical data

| Drive unit: | Geared motor |

| Voltage: | 400/230V-50Hz or as required |

| Sensor: | Motion detector |

| Dimensions: | Refer to drawing and table |

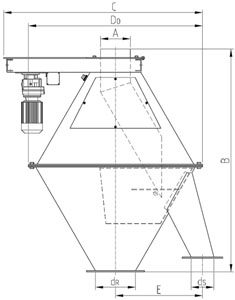

Drawing

Type designation:

The values are only indicative

| Type | Particle size [mm] | øA [mm] | B [mm] | C [mm] | øDO [mm] | ds [mm] | Ødr [mm] | E [mm] | Motor [kW] | Division circum- ference [mm] | Tube speed [rpm] |

| PD8/100 | Max. 25 | 100 | 535 | 705 | 410 | 60×60 | 100 | 170 | 0.25 | 825 | 44 |

| PD12/100 | Max. 35 | 100 | 790 | 1045 | 640 | 60×60 | 200 | 290 | 0.25 | 1255 | 29 |

| PD12/200 | Max. 40 | 200 | 790 | 1045 | 640 | 150×150 | 200 | 290 | 0.25 | 1255 | 29 |

| PD17/100 | Max. 35 | 100 | 1015 | 1095 | 740 | 100×100 | 200 | 330 | 0.37 | 1720 | 21 |

| PD17/200 | Max. 50 | 200 | 1015 | 1095 | 740 | 150×150 | 200 | 330 | 0.37 | 1720 | 21 |

| PD27/100 | Max. 35 | 100 | 1535 | 1370 | 1200 | 100×100 | 200 | 600 | 0,55 | 2700 | 13 |

| PD27/200 | Max. 65 | 200 | 1535 | 1370 | 1200 | 150×150 | 200 | 600 | 0,55 | 2700 | 13 |