Principles of operation

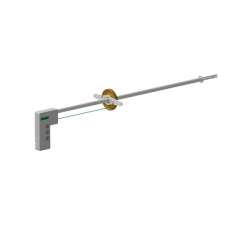

ATD is used to adjust the flow of pulverized coal and bio fuel in feeder pipes between mills and burners. The ATD is flanged into each pulverized fuel feeder pipe.

Download Automatic Trimming Damper brochure (PDF)General description

The flow is adjusted by 2 flaps moving back and forth thus creating a diamond-shaped central opening.

The 2 flaps are synchronically moved by 2×2 gear motors that are placed parallel to the feeder pipe and are in direct contact with the flaps through a gearing.

At receipt of electrical signals it is closing or opening the orifice created by the two flaps. The flaps are moving from opposite sides and form an adjustable diamond shaped opening centrally placed in the cross section of the pipe.

The ATD has an electronic panel with push buttons for activating opening and closing movements of the two flaps. The panel has a digital display which shows the percentage the ATD is presently open (i.e. the area of the actual opening compared to the area of the full cross section of the fuel pipe expressed in percent).

Technical data

| Application: | Balancing of PF flow in PF feeder pipes |

| Drive units: | Geared motors |

| Power supply: | 230V/50Hz or s required |

| Air supply: | Min. 6 bar clean oil-free air |

| Dimension: | According to customers pipe |

| Material: | Flaps in special wear resistant alloy Housing in mild steel |

| Operating temp.: | Max. 150°C |

| Sensors: | Position sensors |

Drawing