Principles of operation

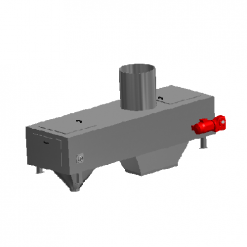

The Mobile Dividing Plant (MDP) is used for representative division of bulk material and can be installed in conjunction with a sampling plant or placed completely independent of the sampling operation.

Download Mobile Dividing Plant brochure (PDF)General description

The material is extracted from the feeding-hopper by a step-less adjustable vibration feeder and dosed into the Rotary Tube Divider. The material is led by gravity through the dividing tube, which passes the respectively sample outlets in the bottom cone.

The Mobile Dividing Plant can be applied on different parts of the production line since the machine is mobile and can be provided with the amount of sample outlets (within a range) that the customer desires.

The MDP essentially consists of the following units:

- Feed hopper

- Vibration Feeder (VF)

- Rotary Tube Divider (PD) (different bottom cones)

- Supporting steel structure with wheels (and stairs)

- Electrical control box with feeder- and vibration control

- Sample containers

Technical data

| Drive unit: | Vibration motor Geared motor |

| Voltage: | 400/230V-50Hz or as required |

| Sensor: | Motion detector |

Drawing

Note: Fore more information to find the plant that suits your needs – please see the brochure for:

- Vibration Feeder (VF)

- Rotary Tube Divider (PD) (different bottom cones)

Type designation:

The values are only indicative

| Type | Feed Hopper Volume [L] |

Rotary Tube Divider Model |

Sample container volume [L] |

Sample Container (QTY) |

| PD8 MDP | 40 (net) | PD8 | Max 2 (net) | Up to 20 |

| PD12 MDP | 80 (net) | PD12 | Max 4 (net) | Up to 20 |

| PD17 MDP | 80 (net) | PD17 | Max 6 (net) | Up to 20 |

| PD27 MDP | 120 (net) | PD27 | Max 8 (net) | Up to 20 |