Principles of operation

The Spinning Riffle Dividing Plant (SRD) is used for representative division of bulk material and can be installed in conjunction with a sampling plant or placed independent of the sampling operation.

Download Spinning Riffle Dividing Plant brochure (PDF)General description

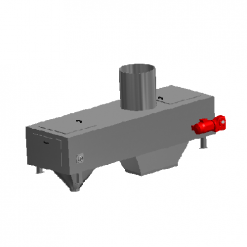

The bulk material is extracted from the hopper by a vibration feeder and dosed into the sample containers placed on the spinning table. The material is led by gravity into the sample containers. The divided samples are collected in sample containers. Each container has an overlapping deflector lip on one side to form cutting edges and prevent loss of fines.

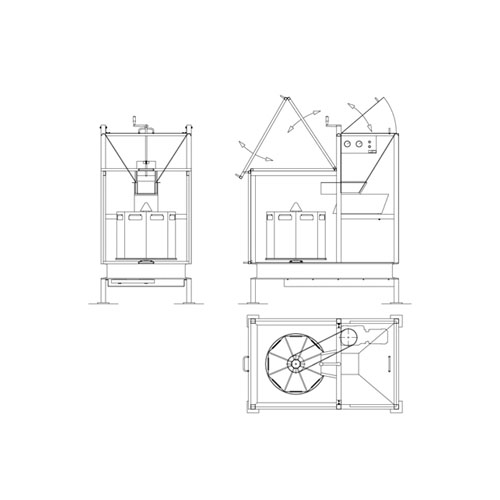

The Dividing Plant consists essentially of the following units:

- Feed hopper with Vibration feeder

- Spinning table for sample containers

- Supporting steel structure

- Safety guard around the spinning table

- Doors for emptying the sample containers

- Electrical control panel with feeder and vibration control

Technical data

| Drive unit: | Geared motor Vibration motor |

| Voltage: | 400/230V-50Hz or as required |

| Sensor: | Motion detector |

| Material: | Stainless steel |

| Dimensions: | Refer to drawing and table |

Drawing

Type designation:

The values are only indicative

| Type | Particle size [mm] | øA [mm] |

B [mm] |

C [mm] |

øDO [mm] |

ds [mm] |

Ødr [mm] |

E [mm] |

Motor 1 [kW] |

Motor 2 [kW] |

Tube speed [rpm] |

Division circum-fer-ence [mm] |

| PD8/100 | 25 | 100 | 535 | 705 | 410 | 60×60 | 100 | 170 | 0.25 | 0.09 | 44 | 825 |

| PD12/100 | 35 | 100 | 790 | 1045 | 640 | 60×60 | 200 | 290 | 0.25 | 0.09 | 29 | 1255 |

| PD12/200 | 40 | 200 | 790 | 1045 | 640 | 150×150 | 200 | 290 | 0.25 | 0.09 | 29 | 1255 |

| PD17/100 | 35 | 100 | 1015 | 1095 | 740 | 100×100 | 200 | 330 | 0.37 | 0.09 | 21 | 1720 |

| PD17/200 | 50 | 200 | 1015 | 1095 | 740 | 150×150 | 200 | 330 | 0.37 | 0.09 | 21 | 1720 |

| PD27/100 | 35 | 100 | 1535 | 1370 | 1200 | 100×100 | 200 | 600 | 0.55 | 0.09 | 13 | 2700 |

| PD27/200 | 65 | 200 | 1535 | 1370 | 1200 | 150×150 | 200 | 600 | 0.55 | 0.09 | 13 | 2700 |